Description:

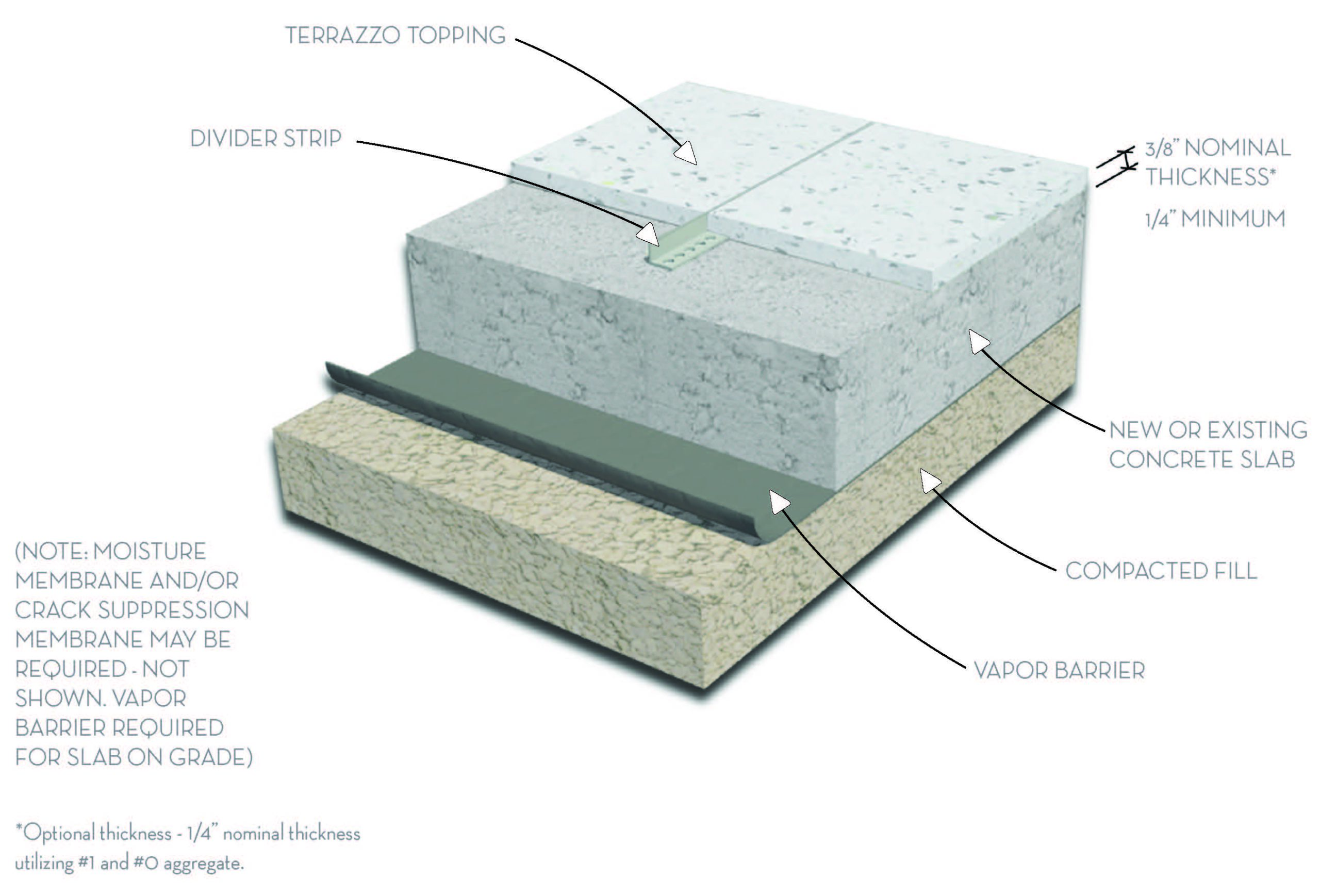

A nominal 1/4″ or 3/8″ thick resin matrix veneer placed upon a level concrete slab; Also can be specified with glass, synthetic, or granite aggregates in lieu of marble to provide brilliant colors or chemical resistance; The best “thin-set” system.

ADVANTAGES:

Unlimited matrix colors, color control, resiliency, chemical resistance and tensile-compressive strengths not found in cement-based systems. Excellent for multi-colored patterns and designs. Lightweight and flexibility make it ideal for multi-story use. It has the lowest maintenance cost due to non-absorbancy. Insanitary areas can be installed with minimal dividers providing seamless characteristics. When used in conjunction with a flexible membrane as a specified extra, it can absorb some horizontal concrete crack or control joint movement. It also has the quickest pour to grind installation time. Can also be used over properly installed and prepared plywood. Glass and other decorative aggregates increased costs.

THICKNESS: Nominal 1/4″ or 3/8″ Epoxy Terrazzo topping. 0-1 chip sizes opt.#2 chip for 3/8″.

WEIGHT: 3-4 lbs. PSF.

DIVIDERS:

Most systems adhere to the concrete and require dividers to be placed precisely above any concrete joints. To prevent the concrete from cracking and therefore the terrazzo, “ACI 302.1 R.89 Concrete Joint Placement” must be followed. Some of these requirements include: Concrete joints should occur a maximum of three times in feet the depth of the concrete in inches. (Example: A 4-inch slab should have concrete joints at a maximum spacing of 12 feet). Concrete joints should run off all corridor intersections and corners. They should not be spaced more than 1.5 times the width of the concrete pour. (Example: A 6-foot wide corridor should have concrete joints at a maximum of 9 feet.)

In addition, other dividers can be set to separate colors or as an accent themselves. In these systems, the dividers not located over concrete joints are strictly decorative. They do not function as leveling devices or crack preventers.

Dividers vary in width from 18 gauge to 1/2 inch. 16 gauge or 1.8 inch are standards. Zinc is standard but brass and colored plastic are readily available.

Architects should design structural inset expansion plates between areas where major movement is anticipated.